OVERVIEW

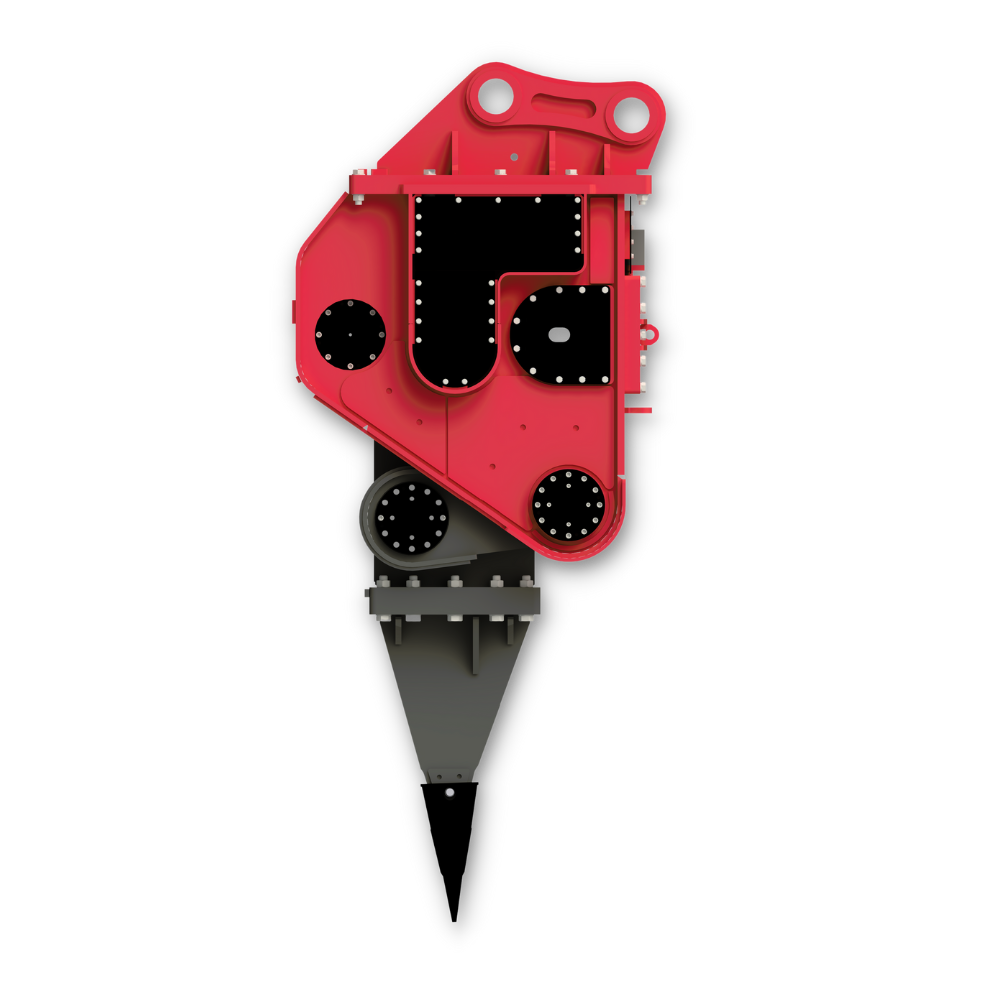

vibrating ripper

available for 20t - 65t

The Vibrating Ripper is an innovative and highly efficient piece of machinery that has been specifically designed to cater to the needs of mining and demolition projects. Utilizing a unique vibrating mechanism, this advanced tool effectively breaks up the ground, resulting in improved penetration into the soil with minimal resistance.

The Vibrating Ripper is the optimal choice when drilling and blasting are not permissible. This is because the vibrating mechanism used by this cutting-edge tool is more controlled, precise and safer, which eliminates the risk of any damage to surrounding structures or the environment.

vibrating ripper

available for 20t - 65t

The Vibrating Ripper is an innovative and highly efficient piece of machinery that has been specifically designed to cater to the needs of mining and demolition projects. Utilizing a unique vibrating mechanism, this advanced tool effectively breaks up the ground, resulting in improved penetration into the soil with minimal resistance.

The Vibrating Ripper is the optimal choice when drilling and blasting are not permissible. This is because the vibrating mechanism used by this cutting-edge tool is more controlled, precise and safer, which eliminates the risk of any damage to surrounding structures or the environment.

CHECK OUT THE VIBRATING PILE DRIVER IN ACTION!

FEATURES

FEATURES

Vibrating Mechanism

Interchangeable Teeth and Chisel

The ability to use either a tooth or a chisel in the same attachment increases worksite efficiency, making it easy to opt for a chisel when needing to break apart larger, more solid materials such as rocks and concrete and the tooth when breaking down compacted soil.

Durable Build

Advanced Protection Design

Heavy Duty Eccentric Gears

The heavy-duty gears increase the torque and kinetic energy, enabling the ripper to generate more force and momentum, resulting in faster and more productive excavations that deliver powerful and efficient performance, breaking through tough materials such as rocks, concrete, and compacted soil with ease.

Robust Construction

Manufactured with hardened pins and larger bushes decreases the overall torsional tension and provides maximum support, extending the Vibrating Ripper's life.

WARRANTY YOU CAN TRUST

GALLERY

GALLERY

.png)

.png)

ABOUT BULLSTERN

ABOUT BULLSTERN

and they have a proven track record of producing attachments that are built to last and perform consistently under the most demanding conditions.

By partnering with BULLSTERN, we are confident that we can provide our customers with world-class products, backed by a team of experts who are dedicated to delivering exceptional quality and service. Our Vibrating Pile Driver and Vibrating Ripper attachments are designed to meet the specific needs of our customers and are suitable for a wide range of applications, from construction and demolition to mining and excavation.

Our partnership with BULLSTERN is just one example of how we are working to achieve this goal, and we look forward to continuing to provide our customers with the best possible products and service in the years to come.

and they have a proven track record of producing attachments that are built to last and perform consistently under the most demanding conditions.

By partnering with Bullstern, we are confident that we can provide our customers with world-class products, backed by a team of experts who are dedicated to delivering exceptional quality and service. Our Vibrating Pile Driver and Vibrating Ripper attachments are designed to meet the specific needs of our customers and are suitable for a wide range of applications, from construction and demolition to mining and excavation.

Our partnership with Bullstern is just one example of how we are working to achieve this goal, and we look forward to continuing to provide our customers with the best possible products and service in the years to come.

.png)

Mr. Yu

VICE PRESIDENT

We prioritize proven performance and quality through a meticulous process of local testing and customer feedback. This approach aids us in identifying and addressing any defects or usability issues that may have been overlooked during the design phase. This sets us apart from many Korean heavy equipment companies with export-oriented businesses, who often neglect the significance of field testing or launch their products into overseas markets without adequate testing.

BULLSTERN has an impressive company background. S & C Co. Ltd., a group specializing in the production of front actuators for construction equipment, has been a successful strategic partner with DOOSAN (previously DAEWOO) since 2000. Additionally, their technical know-how led to an OEM product contract with a leading Japanese brand in 2010, opening new prospects for their own brand attachment business named BULLSTERN.

BULLSTERN's journey, vision, and mission are defined by their motor of sincerity and challenge. With this approach, their mission is to become a global top-tier manufacturer for excavator-mounted attachments specialising in vibrating attachments.

Their top engineers are impressive, more than 30% of all employees are from DAEWOO, and most of them have worked for over 20 years. Mr. Yu, the vice president, is an expert on steel structures and is deeply involved in the design stage of all attachments developed by S & C Co., Ltd. This is why their attachments maintain high durability and long service life compared to others.

.png)

Mr. Yu

VICE PRESIDENT

We prioritise proven performance and quality through a meticulous process of local testing and customer feedback. This approach aids us in identifying and addressing any defects or usability issues that may have been overlooked during the design phase. This sets us apart from many Korean heavy equipment companies with export-oriented businesses, who often neglect the significance of field testing or launch their products into overseas markets without adequate testing.

Bullstern has an impressive company background. S & C Co. Ltd., a group specializing in the production of front actuators for construction equipment, has been a successful strategic partner with DOOSAN (previously DAEWOO) since 2000. Additionally, their technical know-how led to an OEM product contract with a leading Japanese brand in 2010, opening new prospects for their own brand attachment business named Bullstern.

Bullstern's journey, vision, and mission are defined by their motor of sincerity and challenge. With this approach, their mission is to become a global top-tier manufacturer of excavator-mounted attachments specialising in vibrating attachments.

Their top engineers are impressive, more than 30% of all employees are from DAEWOO, and most of them have worked for over 20 years. Mr. Yu, the vice president, is an expert on steel structures and is deeply involved in the design stage of all attachments developed by S & C Co., Ltd. This is why their attachments maintain high durability and long service life compared to others.

-png.png)

-png.png)

HIGH PERFORMANCE

%20(1).png)

.jpg)

Our Vibrating Ripper attachment is a game-changing innovation in excavation technology, designed to provide exceptional performance and versatility in a wide range of excavation applications.

While conventional rock breakers have long been considered the standard option for excavating hard ground types, such as Sandstone, Basalt, Gabbro and Gneiss, as shown in our testing data graph, our Vibrating Ripper attachment has proven to be the superior choice for softer ground types, offering up to 5 times more production than a rock breaker in the 25-50 Mpa range.

By opting for our Vibrating Ripper attachment, businesses can realise significant cost savings, increased productivity and enhanced safety on the job site.

The attachment's superior performance in soft ground types allows for faster completion times, reduced fuel consumption, lower maintenance costs, and improved efficiency, all of which ultimately improve the bottom line.

Our Vibrating Ripper attachment is a proven, highly effective and efficient solution for businesses seeking a high-performance excavation attachment.

LOW DISRUPTION

.jpg)

As shown in this field testing data, the Vibrating Ripper attachment's ability to produce noise levels that are more than 50% lower than conventional rock breakers.

The lower noise levels reduce the risk of hearing damage and other occupational health hazards associated with prolonged exposure to high levels of noise. Additionally, it has positive environmental impacts by reducing noise pollution in the surrounding area.

By looking at the testing data in the graph shown, you see the dramatic difference in disturbance emitted from the use of a conventional Rock Breaker compared to the superior Vibrating Ripper.

%20(1).png)

![]()

Our Vibrating Ripper is engineered with low noise levels in mind, making it the ideal solution for urban areas where noise pollution is a concern. The attachment features an advanced hydraulic motor and vibration mechanism that work in unison to generate minimal noise during operation.

TECHNICAL DATA

%20(4)%20(1).png)

%20(1).png)

![]()

Our Vibrating Ripper attachment is an innovation in excavation technology that has been designed to provide exceptional versatility and efficiency across various industries, including mining and demolition.

At the core of this attachment's capabilities is an advanced vibrating mechanism that effectively breaks up the ground with minimal resistance, making it ideal for demanding excavation tasks.

Compared to conventional rock breakers, the Vibrating Ripper can significantly boost productivity, with users reporting a 3-5 times increase in efficiency, seeing enormous improvements in the yield per hour as seen in the graph.

This translates to faster completion times, which is critical in large-scale excavation projects where time and efficiency are paramount factors in determining the success of a project.

By optimising excavation efficiency, businesses can complete jobs faster and more efficiently, giving them an edge over their competitors when tendering for high-value contracts.

PRODUCTIVITY

![]()

The Vibrating Pile Driver is a versatile piece of equipment that offers significant advantages in pile driving operations. Its 360-degree rotating and 90-degree tilting functions allow the operator to position the machine and pile in the optimal direction, even in tight spaces, increasing the machine's flexibility.The Vibrating Pile Driver is a versatile piece of equipment that offers significant advantages in pile driving operations. Its 360-degree rotating and 90-degree tilting functions allow the operator to position the machine and pile in the optimal direction, even in tight spaces, increasing the machine's flexibility..The Vibrating Pile Driver is a versatile piece of equipment that offers significant advantages in pile driving operations. Its 360-degree rotating and 90-degree tilting functions allow the operator to position the machine and pile in the optimal direction, even in tight spaces, increasing the machine's flexibility

SPECIFICATIONS

SPECIFICATIONS

-

ABPVR (18 - 26T)

-

ABPVR (20 - 36T)

-

ABPVR (38 - 46T)

-

ABPVR (48 - 65T)

-

ABPVR (18 - 26T)NameVIBRATING RIPPER (18 - 26T)FREQUENCY2500 - 3000 bpmSETTING PRESSURE250 bar (3626 psi)RETURN PRESSURE6 bar (87 psi)REQUIRED OIL FLOW170 - 200 L/minSHANK HEIGHT1078 mmBOOT HEIGHT678 mmAVERAGE PRODUCTION RATE20 ~ 30 m3WEIGHT2600 kgMore Info

-

ABPVR (20 - 36T)NameVIBRATING RIPPER (20 - 36T)FREQUENCY2500 - 2800 bpmSETTING PRESSURE250 bar (3626 psi)RETURN PRESSURE6 bar (87 psi)REQUIRED OIL FLOW210 - 230 L/minSHANK HEIGHT1196 mmBOOT HEIGHT761 mmAVERAGE PRODUCTION RATE40 ~ 60 m3WEIGHT3775 kgMore Info

-

ABPVR (38 - 46T)NameVIBRATING RIPPER (38 - 46T)FREQUENCY2200 - 2500 bpmSETTING PRESSURE280 bar (4061 psi)RETURN PRESSURE6 bar (87 psi)REQUIRED OIL FLOW250 - 260 L/minSHANK HEIGHT1296 mmBOOT HEIGHT856 mmAVERAGE PRODUCTION RATE70 ~ 90 m3WEIGHT4880 kgMore Info

-

ABPVR (48 - 65T)NameVIBRATING RIPPER (48 - 65T)FREQUENCY2100 - 2300 bpmSETTING PRESSURE280 bar (4061 psi)RETURN PRESSURE6 bar (87 psi)REQUIRED OIL FLOW290 - 310 L/minSHANK HEIGHT1405 mmBOOT HEIGHT910 mmAVERAGE PRODUCTION RATE100 ~ 130 m3WEIGHT6280 kgMore Info

%20(1).png)

.jpg)

.png)